In this article you will find the answer to the question which often comes up: what the differences between galvalume and galvanized standing seam metal roof are. Both options are equally used for standing seam metal roof, but the property owners as well as the architects often get confused how to tell one from another.

Mon - Sat 8:00 - 18:00

1680 Sismet Rd, Mississauga, ON L4W 1R4

Galvalume vs galvanized standing seam metal roof

What is Galvalume?

Galvalume is also known among specialists as an Aluzinc. It used to be a trademarked name which later acquired a common use. What stands behind the name is a comparatively new material (it was introduced to the market in 1972). Essentially, it is a thin steel sheet, protected not with pure zinc, but with an alloy containing 55.0% of aluminum, 43.4% of zinc and 1.6% silicon.

Galvalume looks quite similar to galvanized steel; however, after closer look one will notice that the surface looks more regular. This is explained by the nature of crystals: they are bigger and stick together closer. Supposedly, you might have also heard the name Galvalume Plus. This is one and the same thing as an ordinary Galvalume, but the first one has thin layer of acrylic coating. This helps to ease the installation and eliminates the necessity of vanishing oil application. The corrosion resistance of this alloy is 6-8 times higher than ordinary zinc. Sometimes polymers are also applied for the coating to expand the color palette. You should keep in mind that Galvalume should not be applied around mortar or concrete because of their alkaline properties which will cause rust and deterioration.

What is galvanized steel?

Galvanized steel is an older material (it was invented back in the 19th century). The sheet it produced through chemical process when carbon steel is briefly put into molten zinc. This process results into “miraculous” properties of the galvanized sheet: it can self-heal the scratches and cuts at the edges.

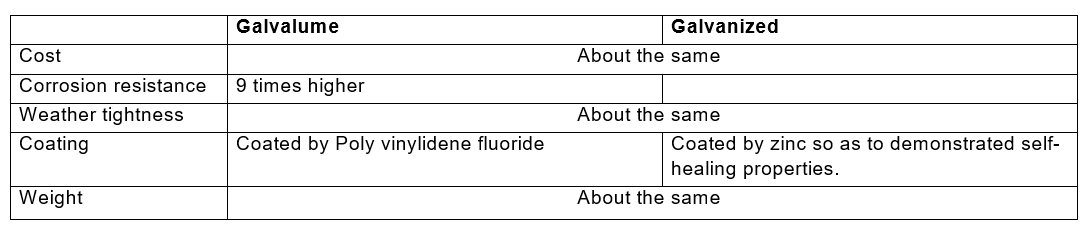

The table will help you to understand the basic similarities and the points of distinction.

In a nutshell, both options are used for standing seam metal roof. However, the Galvalume (or Galvalume Plus) has proved to be more reliable and durable solution. That is why Roof Experts use only hot Zinc coated steel with (275 g/sq.m. or G-90 Zinc amount).