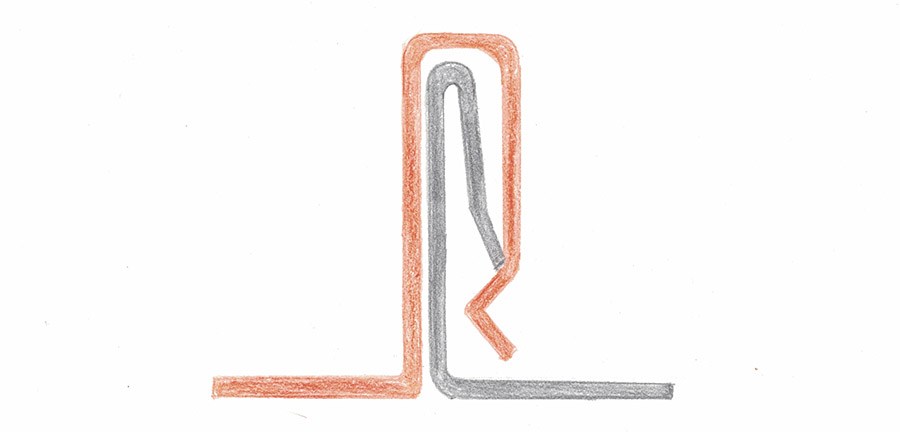

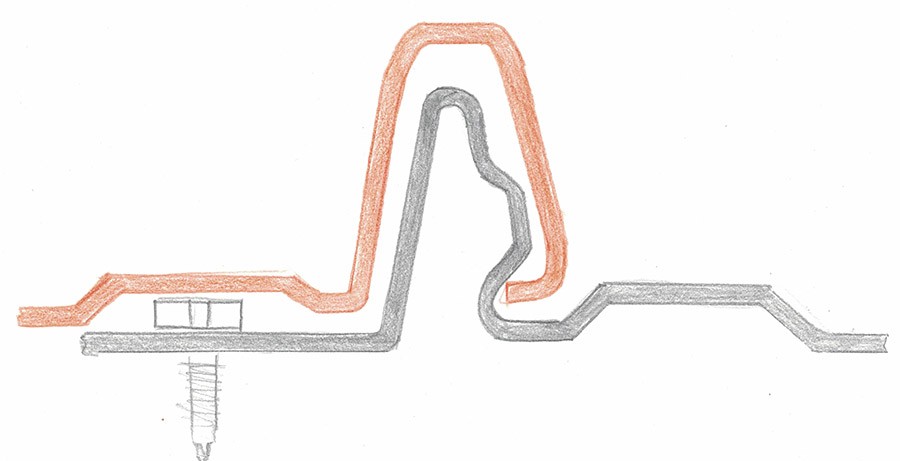

There are many people in Ontario having or considering standing seam metal roofs for residential and commercial properties. Let’s clear out the terms. Standing seam metal roof is called so because you can see the raised interlocking seam which attaches one panel to the nearest other. The most remarkable thing about standing seam is that the fastener is concealed, and there are no holes on the roofing panels. Such seam systems are typically used for metal roofing, or sometimes for metal walls (metal facades).

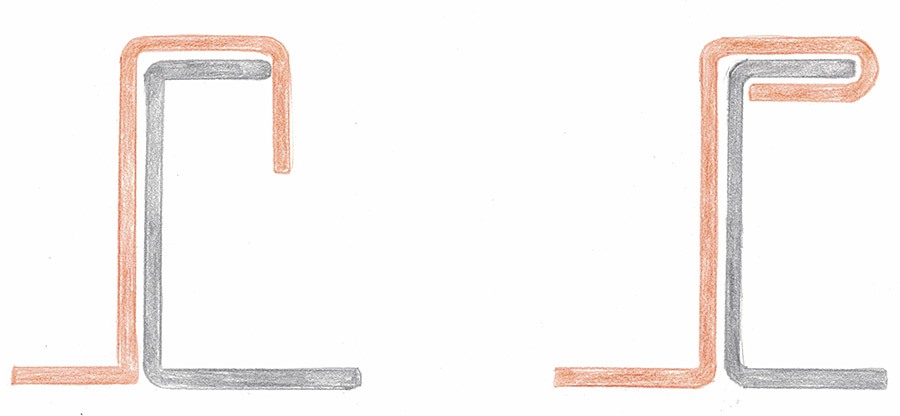

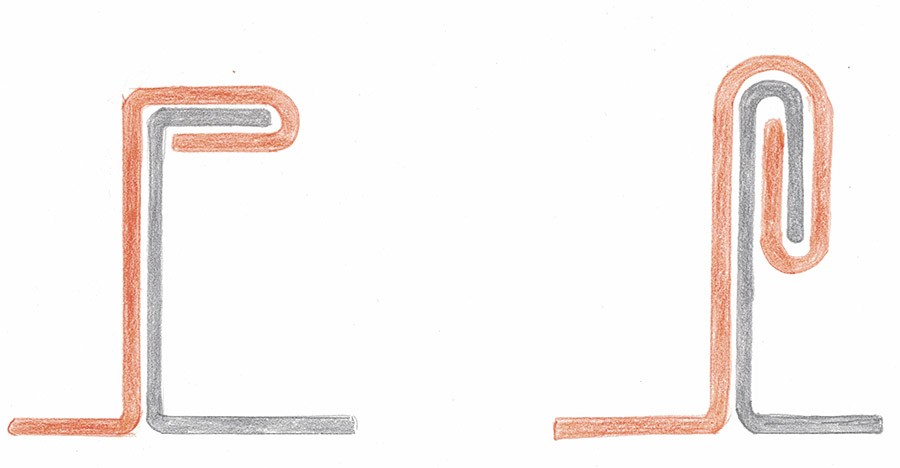

With the standing seam there is almost infinite variety of options for customers: one can choose the color, how long or how wide the panel should be, profile type, as well as shape, thickness and many other possibilities. What is more, there are many kinds of materials from which the profile is made: aluminum, copper, hot zinc coated steel. Below each material will be explained cost-wise as well as from the practical perspective.