Let’s approach the topic of curved standing seam metal roof. Many people wonder how this type of roof came about. Interestingly, it was initially massively used on commercial building, but gradually standing seam arch sheets found their way on residential properties as well. Today it can be argued that curves are totally in.

Mon - Sat 8:00 - 18:00

1680 Sismet Rd, Mississauga, ON L4W 1R4

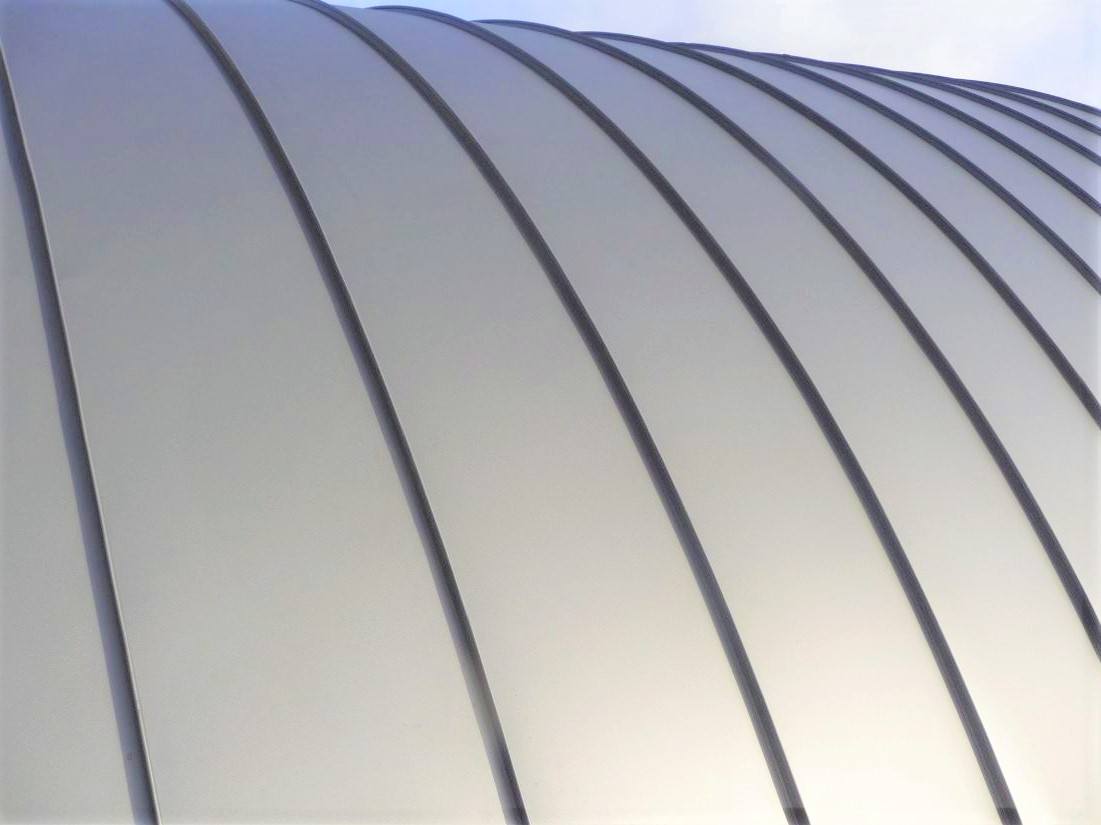

Curved standing seam metal roof

Area of application

At large radius roofing can be used as on industrial buildings, arched warehouses, churches and other non-residential premises with roundish rooftops. Alternatively, curved standing seam is applied as a design accent over the entrance or to visually emphasize the chosen area, for example bay window or porch roof. This highlight to otherwise flat roof adds a visual prominence to the architecture of the home. In addition to the unique exterior, the arched roof gives even more originality to the internal attic space of the building.

Details

Sheets vary in width and height, because different rooftops require sheets of different radius. You might wonder how the panels acquire their curves. In answer to your question, curved panels are mechanically bent by a special radius machine of the required radius directly on a jobsite. The arch bending machine is an ideal tool for the formation of curved portions of a roof, domed and cylindrical elements of a roof. The machine bends prefabricated sheets, of the desired length according to a given radius, without damaging the existing coating. Roofing panel goes through the special slot in a machine getting a desired radius with each pass. The minimum bending radius is about 60 inches (1500 mm). The acceptable spacing of the seams varies between 10 and 30 inches (300 and 800 mm).

Our company has experience in installation of standing seam of any kind and all the necessary equipment. Roof Experts guarantee appropriate and qualitative work whether it is a regular pitched standing seam roof, a roof with a complicated geometry or a curved standing seam roof. Special sheet bending machines and skilled craftsmen will give your roof a truly unique and beautiful look.