Mon - Sat 8:00 - 18:00

1680 Sismet Rd, Mississauga, ON L4W 1R4

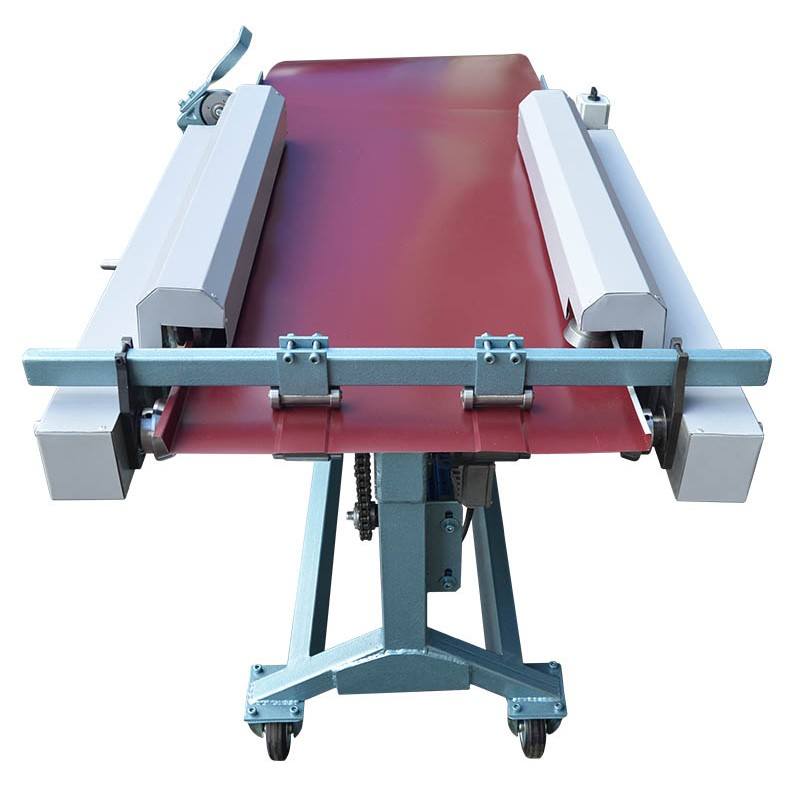

Portable Standing Seam Panel Roll Forming Machine

Rollforming Machines

Recent News

Metal Tile Roof in Kleinberg

Steel snow guards for standing seam metal roof

New Standing Seam in Uxbridge

Recent Posts

Turnkey Metal Building Assembly

Calculating Roof Area

What is the best metal roofing material?

As a business owner or an installer, you might want to get deeper into the machinery needed for faster and top-quality performance. You have the flexibility of using roll forming equipment on site or at the shop for any kind of metal of various length and width as well as for single or double standing seam profiles.

What makes the machine portable?

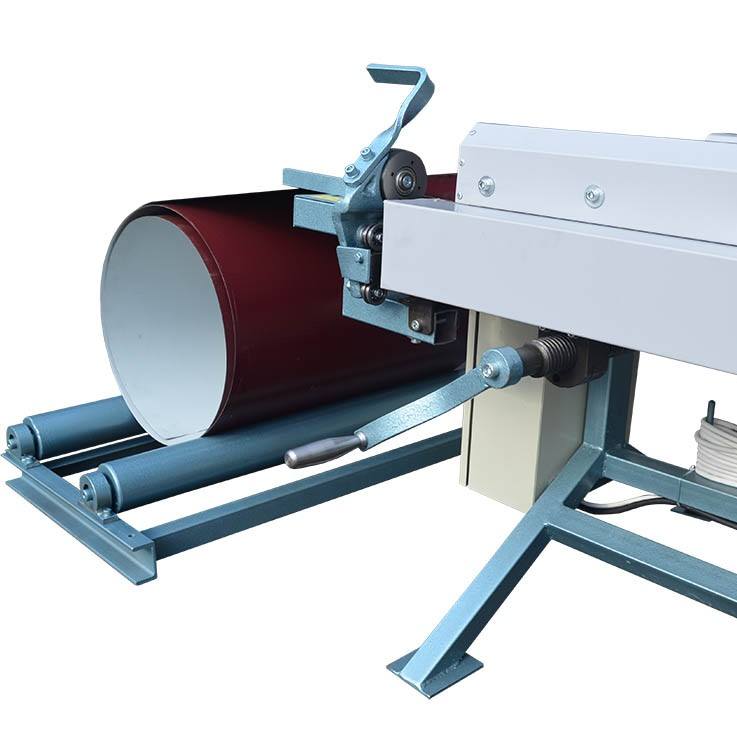

It is not only the size or weight which makes the machine portable to the job site. Also, the whole construction suggests trouble-free transportation and rough conditions of the road. It is easy to disassemble the profiling unit from the frame.

How it works

Now let’s discuss how the metal is fed through the rollers so that you have the desired end shape. With a simple touch of a handwheel you can smoothly regulate the width starting from 320 mm to 700 mm. The rotation of the hand wheel makes the shaping rollers move synchronically.

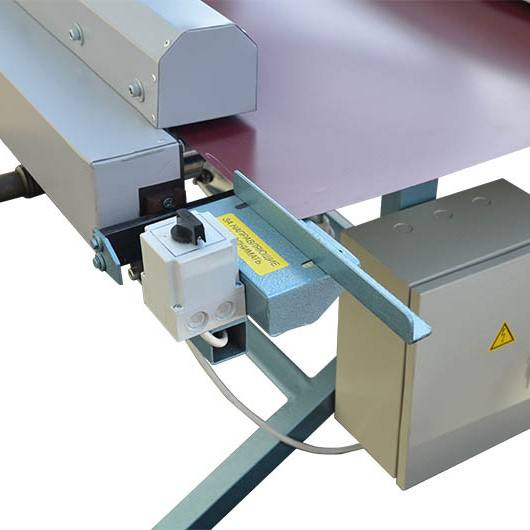

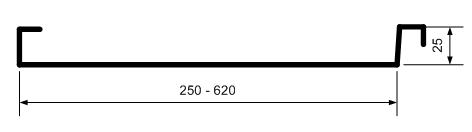

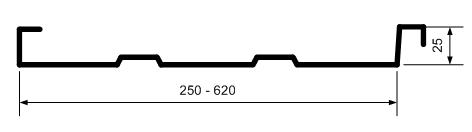

The rollers are the best part about this equipment. Not only there are gauging rollers which help to achieve the needed thicknesses or stiffness; but also, there is a possibility to install additional rollers for semi round or trapezoidal ribs. What is more, thanks to composite rollers there is a zero change of damaging polymer coating. At one of the final stages the panel goes through the last straightening station and then the formed product is cut with a shear or a guillotine at the individual length.

There is a protective cover to exclude any possibility of injury the machine.

| Specifications | |

|---|---|

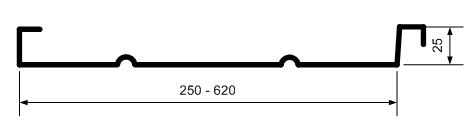

| Infeed width, mm | 320-700 |

| Soft steel thickness, mm | 0.45-0.70 |

| Lock height, mm | 25 |

| Operating speed, m/min | 7 |

| Drive power, kW | 0.75 |

| Supply voltage, V | 110 |

| Dimensions, LхWхH, mm | 1450х960х750 |

| Weight, kg | 150 |

Fill in the form below to order roof roll forming machine.