The article will introduce you to the idea of standing seam insulated roof panels. Some roofers prefer to call them sandwich panels. In essence, these are the panels filled with polystyrene foam, polyurethane foam or polyisocyanurate foam. They are used for the rooftops of various kinds of buildings.

11

Jul

Standing seam insulated roof panels

Why are insulated roof panels used?

Roof is one of the most crucial elements of any structure, as this part faces the greatest impact of aggressive weather and climatic factors, and also protects premises from wind and precipitation. At the same time, the currently accepted construction standards require roofing surfaces to demonstrate presentable appearance, durability, as well as heat and noise insulation. And it is exactly why such modern solutions as standing seam insulated panels are designed to guarantee permanent insulation, do away with thermal bridges and finally, provide unrivaled weather tight and energy-efficient performance.

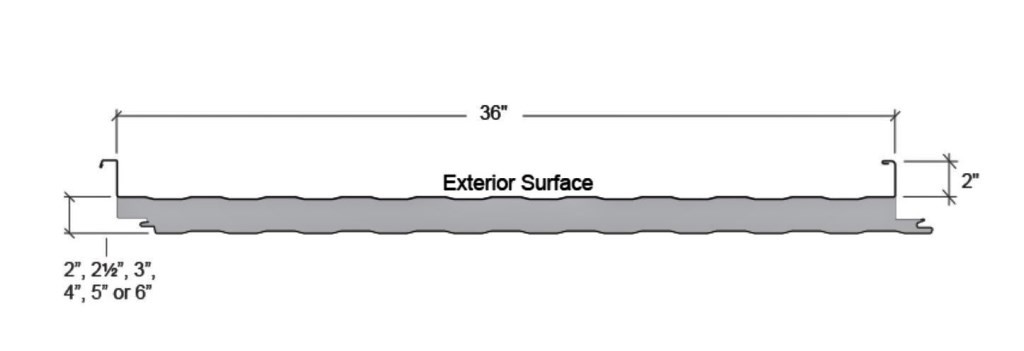

Insulated metal roof panels boast the appearance of classical standing seam roof, but on top of aesthetics they provide the advantages of insulated metal panels: the thermal resistance is very high and so are the qualities of energy efficiency and outstanding fire rating. Easy self aligning assembly reduces construction costs.

How it works

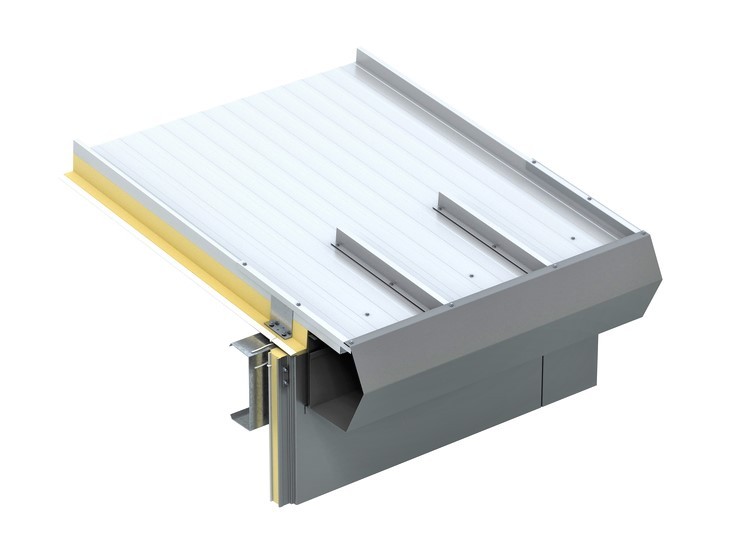

Three-layer sandwich panels consist of two metal sheets, in-between which there is a layer of insulating material. Different materials act as insulators: mineral wool, ordinary fiberglass, polystyrene foam or polyurethane foam.

Metal insulated panels with mineral wool core filler are extremely easy to install. They can be quickly assembled (dismantled) under any conditions. Their advantages are heat resistance and a high degree of heat and sound insulation.

The panels are attached to the property with concealed fasteners. This roof system requires very little field reworking and can be easily and quickly installed.

The exterior surface of the metal sheets is protected by different alloys or compositions. Most often metal sandwich panels are coated with zinc. The thicker layer, the higher is the durability of the material.

Benefits

The main advantages of standing seam insulated panels over most traditional materials include the following:

- Durability. Thanks to the use of modern materials, as well as ultra-resistant protective coatings, the service life of these solutions is close to the service life of the buildings themselves. Panels are not susceptible to temperature deformations, resistant to ultraviolet, demonstrate high biological resistance (protection from mold, moss and fungi), and are suitable for use in all climatic zones of Canada.

- Low weight panels allow you to save on the final cost of the building at the design stage.

- Rigidity and durability. Because of the ribs, roofing panels are self-supporting structures and do not require the installation of additional support frames. High strength characteristics allow them to be used in the construction or repair of virtually any buildings.

- Ease of installation significantly reduce the time and cost of the work.

- Fire resistance of insulated panels can be called one of the most important advantages of these solutions.