Mon - Sat 8:00 - 18:00

1680 Sismet Rd, Mississauga, ON L4W 1R4

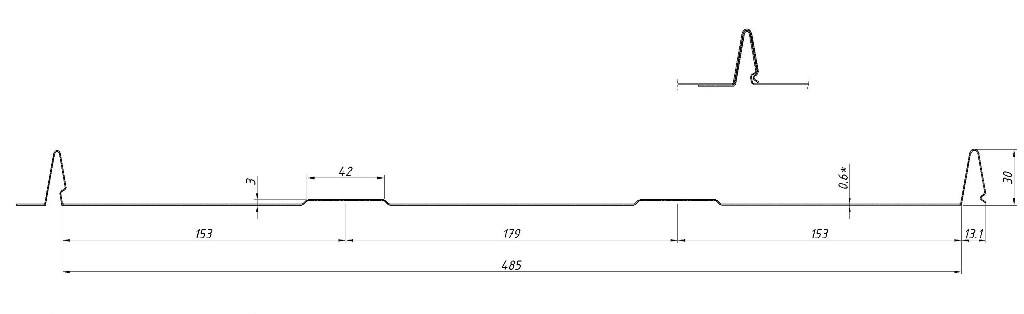

Snap Lock Standing Seam Panel Roll Forming Machine

Rollforming Machines

Recent News

Metal Tile Roof in Kleinberg

Steel snow guards for standing seam metal roof

New Standing Seam in Uxbridge

Recent Posts

Turnkey Metal Building Assembly

Calculating Roof Area

What is the best metal roofing material?

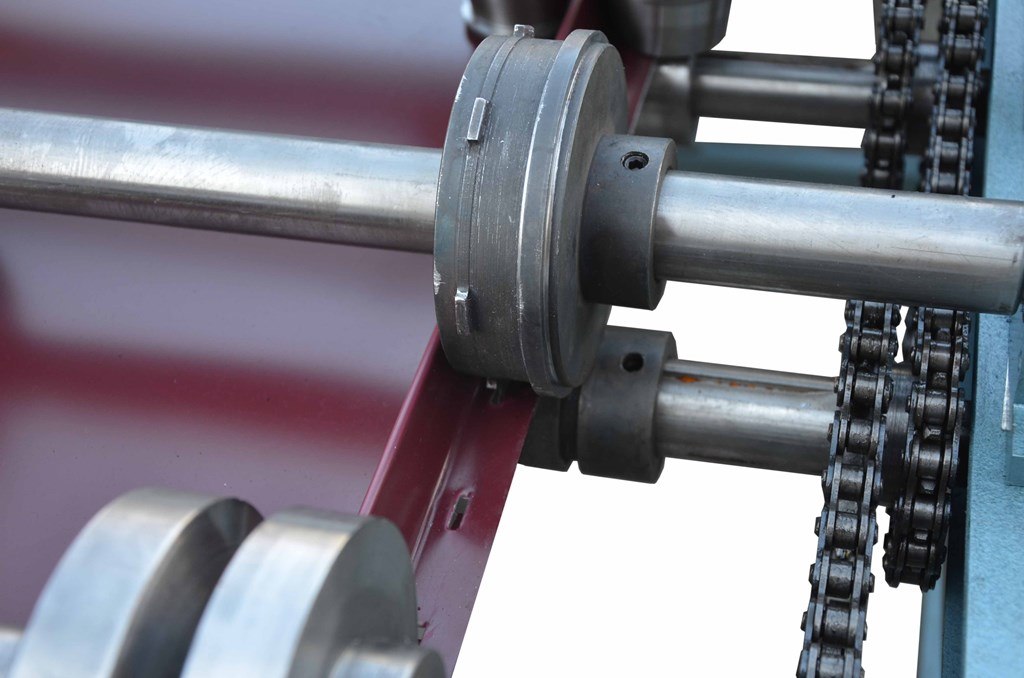

As a roof specialist you might want to look for something to facilitate the installation of snap lock panels for pitch roofs with minimum angle of 15°. The roofing roll forming machine does exactly this job. The equipment is meant for easy manufacture of snap lock standing seam panel. The machine works with any kind of metal. You can adjust length and width manually.

As well as that you can regulate the form of the end product: whether it be straight or trapezoidal. You can also change the pressure force of vertical rollers which will effect the stiffness and thickness of the metal panel. There is also an option to mount extra rollers for half round and trapezoidal ribs. The machine also drills holes for concealed fastening of the panels.

You do not need any additional tools and can carry out the production on site or at the shop.

Please, fill in the form below to discuss questions or details of your order.